In-Depth Analysis of Crankshaft Engine and Its Critical Role in Diesel Engine Performance

The crankshaft engine stands as one of the most vital components in any internal combustion engine, especially in diesel engines which are renowned for their durability and efficiency. An understanding of the crankshaft's design, function, and maintenance can significantly impact the longevity and performance of your diesel engine. At client-diesel.com, we specialize in providing high-quality spare parts and diesel engine components, ensuring your machinery operates at peak efficiency.

Understanding the Crankshaft Engine: The Heart of Power Generation

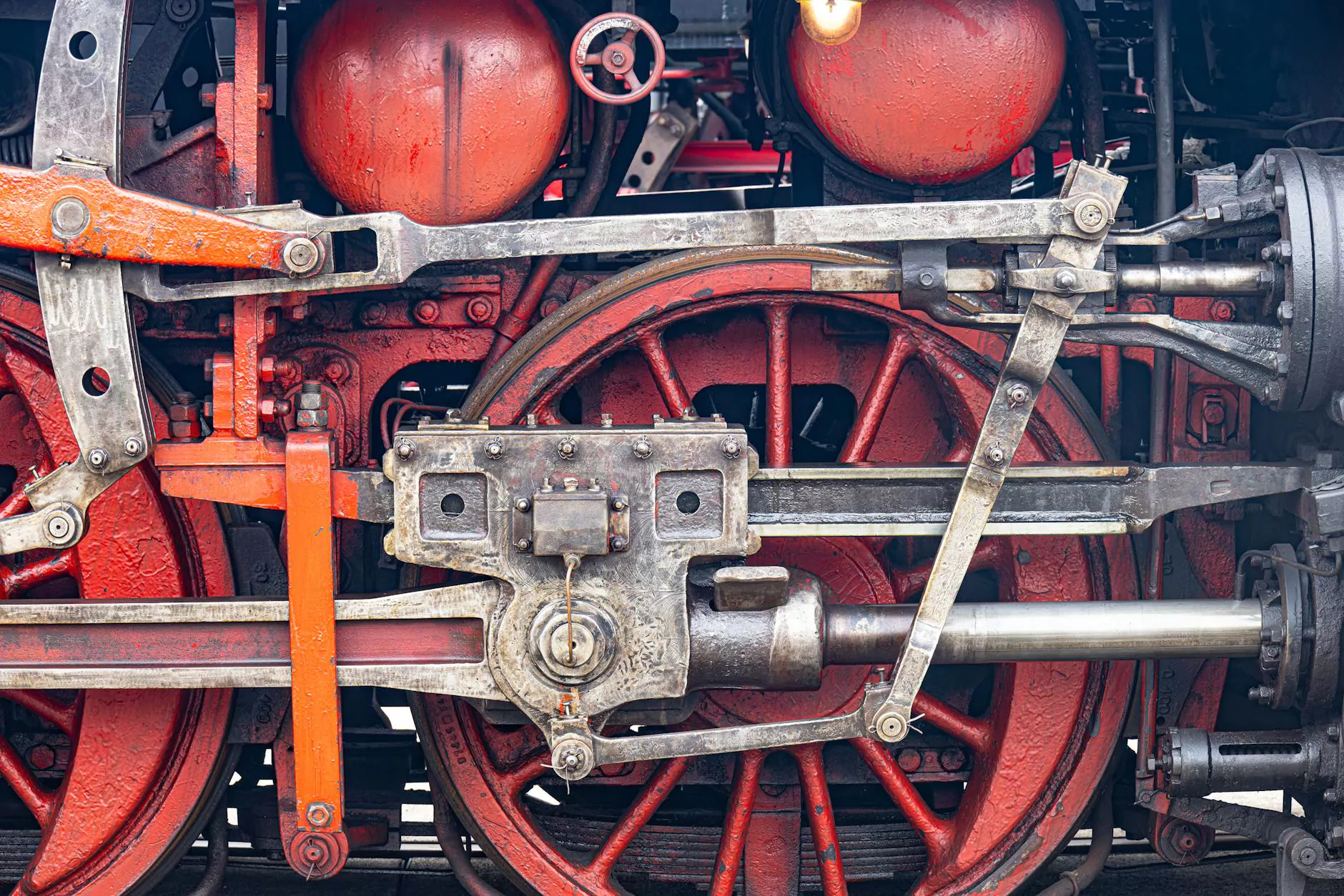

The crankshaft is the core component that converts the linear motion of pistons into rotational motion, enabling the engine to power vehicles, industrial machines, and generators. Its design is intricate, requiring precise engineering to withstand the immense stresses during operation. In a diesel engine, the crankshaft engine must endure high compression ratios, elevated temperatures, and substantial torque outputs, making its durability and quality paramount.

The Anatomy of a Crankshaft Engine

- Main Journals: Bearings that support the crankshaft within the engine block, allowing smooth rotation.

- Connecting Rod Journals: Attach the pistons via connecting rods, translating linear piston motion into rotational motion.

- Counterweights: Balancing components that reduce vibrations and enhance engine smoothness.

- Crankshaft Pins: Connects the connecting rods to the crankshaft, facilitating motion transfer.

- Flywheel: Attached to the end of the crankshaft, maintaining rotational inertia and smoothing engine output.

Critical Functions of the Crankshaft Engine in Diesel Machineries

The crankshaft engine performs several essential functions that make it the backbone of diesel operation:

- Converts Pistons' Linear Motion to Rotational Energy: Ensuring the engine can effectively deliver power to machinery or vehicles.

- Supports Power Transmission: Transmits torque to the transmission system or directly to the wheels in vehicles.

- Maintains Balance and Reduces Vibrations: Offset weights and precise machining minimize engine vibration, ensuring longevity and comfort.

- Acts as a Timing Coordinator: Works in conjunction with timing gears and belts, crucial for synchronized engine operation.

Manufacturing and Material Selection for a Durable Crankshaft Engine

The strength and reliability of a crankshaft engine rely heavily on the materials used and manufacturing processes. High-quality crankshafts are typically crafted from forged steel or cast iron, with forged steel offering superior tensile strength, fatigue resistance, and durability. Advanced manufacturing techniques, such as nitriding and surface treatments, enhance wear resistance and prolong service life.

Why Choose High-Quality Spare Parts from Trusted Suppliers

Ensuring the optimal performance of a crankshaft engine demands the use of premium spare parts. Critical components like bearings, pulleys, and connecting rods must meet strict quality standards to withstand the rigors of diesel engine operation. Suppliers such as client-diesel.com offer a carefully curated catalog of spare parts, designed explicitly for diesel engines, with emphasis on durability, precision, and compatibility.

Features of the Best Spare Parts for Crankshaft Engines

- Superior Material Quality: Ensuring resilience against wear and thermal stresses.

- Precise Manufacturing Tolerances: Guaranteeing perfect fitment and smooth operation.

- Corrosion Resistance: Extending durability in harsh environments.

- Compatibility Assurance: Sourcing parts that match your engine specifications precisely.

- Competitive Pricing: Balancing cost-effectiveness with high standards of quality.

Maintenance and Upkeep of Crankshaft Engines

Proper maintenance is essential to maximizing the lifespan of the crankshaft engine and preventing costly repairs. Routine inspections, lubrication, and timely replacement of worn-out spare parts keep the engine running smoothly. Key maintenance practices include:

- Regular oil changes with high-grade lubricants designed for diesel engines.

- Monitoring for unusual vibrations or noises indicating potential issues.

- Inspecting the crankshaft bearings and journals for signs of wear or damage.

- Replacing damaged or worn spare parts promptly to prevent further damage.

Advancements in Crankshaft Engine Technology

Innovative engineering and materials science continue to push the boundaries of crankshaft engine performance. Modern designs incorporate counterweight optimization, lightweight alloys, and surface hardening techniques to improve fuel efficiency, reduce emissions, and extend operational life. Additionally, the advent of computer-aided design (CAD) and manufacturing (CAM) ensures high-precision production that meets exacting standards, vital for diesel engines subjected to severe operational conditions.

Choosing the Right Spare Parts Suppliers for Your Diesel Engine

Partnering with reputable spare parts suppliers guarantees access to authentic, durable, and high-performance components. Companies like client-diesel.com have established trust through:

- Comprehensive product ranges covering all crankshaft related parts.

- Adherence to international quality standards and certifications.

- Expert technical support and guidance for parts selection and installation.

- Fast delivery times and competitive pricing models.

- Proven track record of serving OEMs, aftermarket businesses, and individual mechanics.

Future Trends in Diesel Crankshaft Engine Technology and Parts

The future of crankshaft engine technology lies in sustainable materials, additive manufacturing, and integration with advanced diagnostics. The development of lightweight, high-strength alloys will further optimize engine efficiency. Additionally, digital monitoring systems embedded within crankshaft assemblies enable real-time performance tracking, predictive maintenance, and failure prevention. As the industry evolves, so does the importance of sourcing spare parts from innovative suppliers committed to quality and technological advancement.

Conclusion: Elevating Diesel Engine Performance with Quality Crankshaft Engine Parts

Recognizing the critical role of the crankshaft engine in the overall performance, fuel efficiency, and durability of diesel machinery is essential for business owners, mechanics, and engineers alike. By investing in top-tier spare parts from trusted suppliers such as client-diesel.com, you ensure your engines operate reliably under demanding conditions. Embracing innovations and maintaining rigorous upkeep will not only extend your engine’s lifespan but will also improve operational efficiencies, reduce downtime, and safeguard your investments in diesel technology.

Remember, quality components and proper maintenance are your best allies in achieving optimal diesel engine performance, especially in applications relying on the robust and resilient crankshaft engine.